An Introduction to Extended Producer Responsibility (EPR)

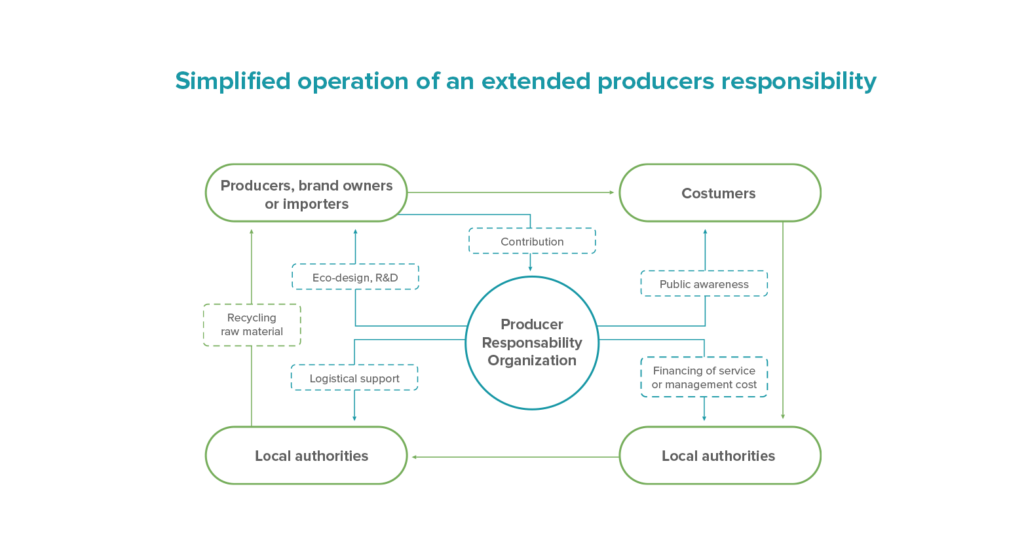

Extended Producer Responsibility (EPR) is a policy approach designed to make manufacturers responsible for the lifecycle of their products, including post-consumer disposal. The concept places accountability on producers to manage the environmental impact of their goods, encouraging sustainable practices from design to end-of-life management.

A 2023 study by The Recycling Partnership investigated how Extended Producer Responsibility (EPR) influenced the outcomes of seven global paper and packaging recycling initiatives. Results indicated that implementing EPR policies significantly increased the collection of designated materials. Specifically, British Columbia, Belgium, Spain, South Korea, and the Netherlands demonstrated rates surpassing 75%, while Portugal and Quebec achieved rates exceeding 60%.

EPR stands as a powerful mechanism to align economic growth with environmental sustainability. Its adoption by manufacturers worldwide is a critical step toward creating a circular economy that conserves resources, minimizes waste, and fosters a more sustainable future.

Understanding the Key Points of Extended Producer Responsibility (EPR)

EPR significantly departs from conventional waste management, transferring responsibility from public entities to producers. This approach transforms waste management into an integral aspect of the product lifecycle, alleviating the burden on governments and the average consumer. The following are the 5 most impactful benefits of Extended Producer Responsibility.

- Environmental Impact

Under the umbrella of Extended Producer Responsibility (EPR), producers shoulder the responsibility for the entire journey of their products, mainly focusing on end-of-life considerations. This paradigm urges a comprehensive examination of environmental consequences, from raw material extraction to disposal, ensuring meticulous management of products in an ecologically sound manner. - Product Design

Central to EPR is the cultivation of eco-friendly design practices. Producers are motivated to engineer products that facilitate disassembly, recycling, or repurposing, curtailing waste production and safeguarding precious resources. This proactive approach ensures that environmental consciousness is built into a product’s inception. - Production Accountability and Incentives

EPR reshapes the production phase by infusing environmental responsibility into manufacturing processes. Manufacturers are compelled to design and produce with end-of-life considerations at the forefront. This approach catalyzes the integration of sustainable and circular principles from the product creation. EPR policies, introduce economic incentives like tax breaks or subsidies, counterbalanced by fines for non-compliance. - Influence on Consumer Behavior

EPR possesses the potential to mold consumer behavior by fostering awareness about the environmental footprint of products and encouraging choices that align with sustainability. This involves active participation in recycling programs and making well-informed purchasing decisions. - EPR as a Circular Economy Catalyst

Positioned as a pivotal tool in advancing the tenets of the circular economy, EPR propels producers towards crafting products that seamlessly fit into a circular production and consumption model—easy to recycle, repair, and reuse. This marks a deliberate departure from linear practices towards a more regenerative and sustainable approach.

Importance of Circular Supply Chains

With supply chain disruptions caused by the COVID-19 pandemic, enterprises are increasingly reevaluating the conventional supply chain model. The unprecedented global impacts of 2020 affected trade, finance, health, education systems, businesses, and societies, highlighting the need for a shift in supply chain management.

In a 2023 EY survey, 72% of companies reported experiencing a negative impact during the pandemic, with only 2% stating they were fully prepared. As businesses strive to mitigate the fallout of such disruptions, there is a growing recognition of the imperative to foster more adaptable and interconnected supply chains to navigate unforeseen challenges effectively.

Businesses increasingly turn to the circular economy to redesign their supply chains. This shift addresses the imperative for adaptability and allows companies to cut costs and mitigate their environmental impact. Circular supply chains require establishing distributed and interconnected networks, enabling local and global partnerships with suppliers, customers, and industry peers.

Extended Producer Responsibility (EPR) and circular supply chains intersect at the core of sustainable and responsible product lifecycle management. They are convergent in their shared objectives of promoting responsible production, reducing waste, and maximizing the value of materials within a sustainable and circular economy framework. Here is where EPR and circular supply chains meet:

Supply Chain and Lifecycle Responsibility

EPR encourages manufacturers to design products with the entire lifecycle in mind, promoting durability, recyclability, and reusability. Circular supply chains aim to keep products and materials in use for as long as possible, aligning with the concept of responsible product design advocated by EPR.

Waste Management in Production

EPR programs hold producers accountable for the proper disposal and recycling of their products, fostering a circular approach to waste management. Circular supply chains emphasize reducing waste and maximizing the value of materials through recycling and other sustainable practices, aligning with the goals of EPR.

Collaboration Across the Supply Chain

EPR requires collaboration between manufacturers, consumers, and recycling facilities. This collaboration is fundamental to circular supply chains, where interconnected networks facilitate the efficient flow of information, goods, and materials. EPR and circular supply chains promote stakeholder partnerships and collaboration to achieve common sustainability and business goals.

Resource Conservation and Material Efficiency

EPR encourages responsible resource management by promoting the efficient use of materials and reducing environmental impacts. Circular supply chains inherently focus on resource conservation by extending the lifespan of products and materials, reducing the need for new raw materials.

Environmental Impact Reduction

EPR aims to reduce the overall environmental impact of products, especially in terms of end-of-life management. Circular supply chains, by promoting a closed-loop system, contribute to lowering environmental impacts through reduced waste generation and sustainable resource use.

EPR Challenges & Greenwashing Concerns

Implementing Extended Producer Responsibility (EPR) poses multifaceted challenges, navigating human and technical dimensions. People-related hurdles, including resistance to change, can hinder the smooth execution of EPR programs. Project management complexities arise from the various phases involved, such as planning, development, and testing, necessitating meticulous coordination among stakeholders. The involvement of multiple departments, each juggling diverse priorities, adds a layer of complexity, requiring practical project and people management. Successful EPR implementation hinges on realistic expectations, clear communication, and crucial backing from executives.

Another hurdle lies in technology and data integration, a fundamental aspect of EPR. Locating and migrating data from disparate sources into the ERP database demands meticulous planning. Challenges emerge in identifying the scattered data stored in various formats and systems across the organization. Data quality becomes a substantial concern, with potential issues such as duplicates, inconsistencies, and outdated information.

Change management presents a significant challenge in EPR implementation; resistance to change can impede progress, necessitating early buy-in from leadership and stakeholders. Additionally, EPR projects are notorious for cost overruns. Underestimating the resources needed, especially for customization and data migration, can lead to increased spending. Businesses should meticulously budget for overlooked expenses, ensuring finances for the entire project duration. Finally, EPR implementation demands continuous improvement, with periodic reviews to assess whether the system aligns with evolving business demands and technology.

Another critical challenge comes from Greenwashing in EPR, which occurs when companies make misleading claims about their commitment to environmental practices. This can involve incomplete or superficial commitments without genuine integration of EPR practices and goals. Stakeholders, including consumers and regulatory bodies, must scrutinize and hold companies accountable, questioning misleading marketing that overstates environmental responsibility or a lack of transparency in reporting on EPR initiatives.

Looking Forward and The Consumers’ Role in EPR

Consumers can influence the future of Extended Producer Responsibility and circular supply chains by making sustainable choices that drive market demand for environmentally responsible products. Their informed decisions and preferences encourage businesses to adopt robust EPR practices. Additionally, consumer awareness serves as a catalyst for advocating stronger EPR regulations, fostering discussions, and prompting policy changes. Consumers play a crucial role in driving a more sustainable and circular future by actively participating in and influencing the EPR landscape and market.

In conclusion, as we delve into the landscape of EPR, it becomes evident that this paradigm shift is not just about rethinking waste management; it’s about transforming the core of production and consumption systems. EPR challenges us to envision products not just as commodities but as entities with lifecycles demanding careful reconsideration.

To all stakeholders – from producers and policymakers to consumers and environmental advocates – the time to embrace EPR is now. The challenges are real, from navigating data integration to overcoming resistance to change, but the potential benefits are immense. We can pave the way for a more sustainable and circular future.

Through EPR, we have the opportunity to shape a world where the environmental impact of every product is not an afterthought but a fundamental consideration. The potential is within our grasp – let us seize it for a circular future.